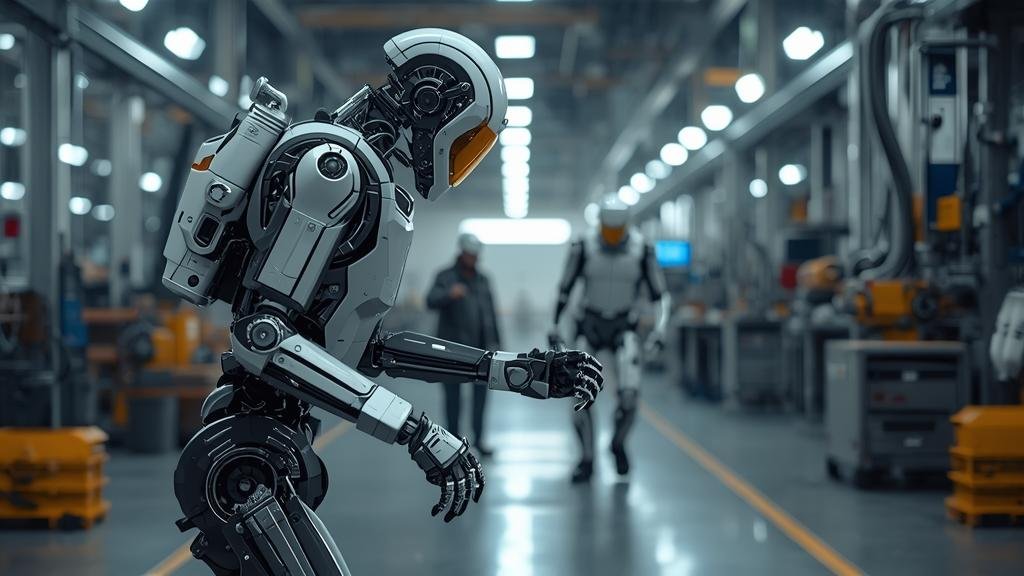

Bionic Labor: Exoskeletons in 2026 Factories

Factory floors in 2026 are seeing a surge in Exoskeletons for Work as production lines ramp up and skilled labor remains tight. Major automotive and logistics operators have moved from pilot programs to fleet deployments, targeting repetitive strain injuries and throughput bottlenecks. The shift isn’t about replacing workers; it’s about keeping them on the line longer and safer.

Alongside the hardware, the broader category of Human Augmentation is maturing fast, with better batteries, smarter actuators, and tighter integration into warehouse systems. The net result is a practical ROI story: fewer injuries, faster cycle times, and lower training overhead.

Quick takeaways

-

- 2026 models are lighter, smarter, and easier to fit than early-gen units.

-

- ROI shows up in injury reduction and cycle-time gains, not just novelty.

-

- Integration with WMS/MES is now a standard requirement, not a bonus.

-

- Fit and training matter more than raw torque specs.

-

- Privacy and data controls need to be negotiated upfront with vendors.

What’s New and Why It Matters

In 2026, exoskeletons for work are no longer bulky prototypes; they are purpose-built tools for specific motions: overhead lifts, sustained squat holds, and long-duration standing. The newest units use brushless actuators and passive spring systems to offload shoulder and lower-back load without adding bulk. Battery life has jumped into the 10–14 hour range for active units, and passive units remain weight-neutral for full shifts.

What’s changed is the software layer. Actuation profiles now adapt to the operator’s cadence using low-latency IMUs and simple machine learning models that learn a worker’s gait and lift style. Supervisors can set motion limits per role, and the devices can log exposure to high-risk movements. This turns exos from “wearable assistance” into a safety and productivity platform.

Why it matters: the cost of a single back injury can erase the savings from dozens of underperforming shifts. With tightening labor markets and aging workforces, factories are prioritizing tools that reduce strain without slowing throughput. Exoskeletons for Work have become a hedge against absenteeism and a way to keep experienced operators on the floor. At the same time, the broader trend of Human Augmentation is pushing vendors to deliver more intuitive, less intrusive designs that feel like part of the uniform rather than an add-on.

Key Details (Specs, Features, Changes)

Compared to the 2022–2023 generation, 2026 units are lighter and more modular. Passive shoulder exos now weigh under 1.5 kg and use adjustable spring tension to match lift profiles. Active lumbar units deliver 150–250 N of assistive force at peak, with torque curves tuned to the user’s height and leg length. Many models offer quick-swap batteries and tool-free adjustments, cutting fit time from 15 minutes to under 5.

Connectivity is standard. Devices can pair with WMS/MES systems via Bluetooth Low Energy or Wi‑Fi and expose APIs for event logging. Safety features include motion geofencing (e.g., disable assist near pinch points), fall detection, and “buddy alerts” when a user exceeds preset fatigue thresholds. The software also supports role-based profiles, so an overhead press operator gets a different assist curve than a packer. Compared to before, the focus has shifted from raw power to controllability and safety.

How to Use It (Step-by-Step)

-

- Pre-shift sizing: Measure hip-to-shoulder and torso length; select the frame size and set spring tension or motor bias. A proper fit should feel snug but not restrictive; the device should track your natural motion without fighting it.

-

- Profile setup: In the companion app, assign a role (e.g., Overhead Assembly). Set assist strength (start at 40%), motion limits (max shoulder angle), and alerts (fatigue threshold). Sync to the device.

-

- Warm-up and calibration: Perform five controlled lifts and squats to let the IMUs calibrate. Confirm zero-point alignment for the spine or shoulder joints. The device should “learn” your baseline posture.

-

- Work cycle: Begin the shift. For active units, toggle assist only when needed (e.g., overhead work). For passive units, ensure straps remain snug after 30 minutes. Keep the battery above 20% before breaks.

-

- Mid-shift check: Check hotspots and strap tension. If you feel rubbing, adjust pads or add a thin undershirt. If the device “pulls” in the wrong direction, recalibrate in the app.

-

- Data and feedback: Review end-of-shift metrics: high-risk motions, total load, and time-in-zone. Share with supervisors to refine profiles. If pain persists, request a different frame or assist curve.

Real-world example: an overhead line operator in an auto plant reduced shoulder strain by pairing a shoulder exo with a 60-second micro-stretch routine every hour. Throughput improved by 6% after two weeks. Note: the exact gains depend on task layout and training quality.

Practical tips: keep spare pads on hand, label units by size, and assign a “fit captain” per shift to handle quick adjustments. Use the highlighted resources for more context on Exoskeletons for Work and the evolving field of Human Augmentation.

Compatibility, Availability, and Pricing (If Known)

Most 2026 units support iOS and Android apps and integrate with common WMS/MES via REST APIs or MQTT. Bluetooth 5.x is standard; some plants prefer Wi‑Fi for centralized logging. Compatibility with existing PPE is generally good, but check glove and sleeve interference around straps. Passive units fit a wider range of body types; active units may require specific frame sizes.

Availability varies by region. Vendors typically ship demo units for pilot testing before full fleet orders. Pricing is not standardized; it depends on configuration, software licenses, and support tiers. Expect higher upfront cost for active units and lower ongoing costs for passive units due to fewer electronics. Most vendors offer leasing or subscription models that bundle maintenance and firmware updates.

Common Problems and Fixes

- Symptom: Rubbing or hotspots on the shoulders or hips.

Cause: Straps overtightened or misaligned with body landmarks.

Fix: Loosen straps, reposition pads to bony areas, add breathable liners, and reroute straps away from nerve paths. - Symptom: Device feels like it’s fighting your motion.

Cause: Calibration drift or wrong profile.

Fix: Recalibrate, verify role profile, and reduce assist strength by 10% increments until motion feels natural. - Symptom: Battery draining mid-shift.

Cause: High assist levels or cold environment.

Fix: Swap to a spare battery, lower assist for low-intensity tasks, and store batteries at room temperature. - Symptom: Data not syncing to the dashboard.

Cause: Bluetooth/Wi‑Fi interference or device out of range.

Fix: Move closer to the gateway, toggle airplane mode, update firmware, and confirm network credentials. - Symptom: Muscle fatigue or new soreness.

Cause: Over-reliance on assist or poor posture.

Fix: Reduce assist, schedule micro-breaks, and run a quick posture refresher with the supervisor.

Security, Privacy, and Performance Notes

Exoskeletons collect motion, posture, and usage data. Treat this as sensitive. Negotiate data ownership and retention in the purchase agreement. Prefer vendors that support on-premise data storage or regional cloud hosting. Ensure role-based access control so only authorized supervisors can view individual metrics. Avoid sharing raw biometric traces outside the plant without explicit consent.

On the performance side, balance assist levels with task requirements. Too many assists can reduce proprioception and increase the risk of moving machinery. Set geofenced limits around pinch points and require daily self-checks for wear and tear. Keep firmware updated to patch safety logic and improve battery management. Finally, measure outcomes beyond throughput: track injury rates, reported discomfort, and shift-end fatigue scores to validate ROI.

Final Take

Exoskeletons for work have graduated from experimental gear to standard safety equipment on many 2026 factory floors. The winning deployments pair smart fit, role-based profiles, and clear data policies. When done right, they reduce strain, stabilize output, and extend the careers of experienced operators. The key is to pilot, measure, and iterate—don’t force a single profile across all tasks.

If you’re evaluating vendors, start with a targeted use case (overhead lifts or long-duration standing), run a 30-day pilot, and track both safety and throughput metrics. For a broader context, review our guide on Exoskeletons for Work and check industry coverage on Human Augmentation.

FAQs

Q: Do exoskeletons replace workers?

A: No. They reduce physical strain and help workers maintain pace, especially in repetitive or overhead tasks. Most plants deploy them to retain experienced staff and cut injury rates.

Q: How long does training take?

A: Basic fit and use can be taught in 30–45 minutes. Competent daily use typically takes 1–2 shifts to internalize, especially for adjusting straps and profiles mid-shift.

Q: Are active units always better than passive?

A: Not necessarily. Passive units are lighter, require no charging, and suit many tasks. Active units shine where sustained torque or lumbar support is critical. Match the tool to the motion.

Q: What about hygiene and shared units?

A: Use removable, washable pads and assign units per operator when possible. If sharing, sanitize straps and contact surfaces between shifts, and keep spare pads stocked.

Q: How do we measure ROI?

A: Track injury incidence, lost-time incidents, cycle times, and operator-reported fatigue. Compare pre- and post-deployment baselines over at least 30–60 days.